!!!Buying iron pellets, and what you need to know about iron pellets

| عکس | کد | نام | واحـد | قیمت | عملیات |

|---|---|---|---|---|---|

| Iron ore pellet of Ardakan steel smelting | تماس بگیرید | |||

| Iron ore pellets of Butiai Iranian iron ore | تماس بگیرید | |||

| Iron ore pellets of Butiai Iranian iron ore | تماس بگیرید | |||

| Chadormelo iron ore pellet | تماس بگیرید | |||

| The iron ore ball of the ground | تماس بگیرید | |||

| Iran’s central iron ore pellet | تماس بگیرید | |||

| Parsian Sangan opal iron ore pellet | تماس بگیرید | |||

| Gol Gohar iron ore pellet | تماس بگیرید |

?What is iron pellet and what are its uses

- Iron pellet It means pellets produced from soft rock and other additives that are first creamed and then baked and hardened. And it is used for regeneration using the traditional method of iron production in a blast furnace or multiple methods of direct regeneration.

- Iron pellets in English are small spheres that are made from combining iron ore with other products to create materials that are easy to transport. In other words, pellets are balls containing iron that are sold in the form of crushed powder and spherical masses.

- These pellets are the main raw material for the production of steel and various metals in the blast furnace. The size of these pellets varies from 2 to 30 mm in diameter. The most common iron pellets are pellets with a diameter of 10 to 15 mm.

- For the production of these pellets, iron ore from mines that are not rich in iron are used, and various wastes containing iron are used in their composition. Also, the price of iron pellets varies depending on the manufacturer and its composition.

- The most important application of these pellets is related to iron and steel production industries. If you need to buy iron pellets and get information about the price of iron pellets, we suggest you contact the mine iron sales consultants.

- It is worth mentioning that iron ore pellets are mainly used in the process of melting steel and various metals in blast furnaces. It is good to know that unlike agglomerated ore concentrate, pellets can be transported and stored for a long time without any degradation.

Table of contents

An introduction to iron ore and iron concentrate

- Iron ore occurs naturally in the form of rocks mixed with other elements. Iron ore is processed through various industrial processes using advanced technology and then sold to steel companies. Iron ore concentrate is an enriched product in which the content of elements and mineralogical composition more closely matches the requirements for metallurgical processing. The development of the technology of pumping iron ore concentrate in the furnace through the nozzle (with coal dust or independently) is one of the most promising fields of blast furnace production, which can significantly replace lump ore.

- Iron pellets can be mentioned as an example of products obtained from iron ore concentrate. In general, an iron pellet is a small ball of iron ore that is used in the production of steel. Iron ore pellets with a minimum iron content of 62% are used in blast furnaces to produce iron. In other words, the metallization pellets obtained from the improved concentrate contain at least 66% iron and are mainly used for the production of direct reduced iron.

The nature of iron pellets

- Pellets are fine iron grains that have been ground into spherical balls and have good physical properties for bulk and mechanical transportation over long distances. Also, pellets have excellent metallurgical properties similar to or even better than mineral stones. In fact, pellets are used as a raw material to replace sinter or ore in iron production factories.

- It is worth mentioning that pellets are preferred over iron ore powder and lumpstone due to their shape, size, strength and excellent metallurgical properties in blast furnaces. Due to the reasonable price of this product, the use of pellets has led to an increase in the productivity of iron-making units, which have limited capital.

- Iron pellets are one of the types of metal products that are made from finely dispersed ore components. It is worth noting that these ore pellets have a great contribution to the performance of blast furnaces, they reduce the concentration of slag in the processing of metal ores, and they also have a significant contribution to the smelting of iron and steel. It should be noted that the composition and chemical formula of iron pellets mainly consists of iron ore concentrate, glue and various organic materials such as bentonite, molasses, starch, etc.

Characteristics of iron pellets

- The most important characteristics of iron pellets can be described as follows

- Iron ore pellets are round granules and are produced from iron ore enrichment (moistened iron ore concentrates).

- In the production process of these pellets, in the initial stage, small ore and mineral additives are removed and then it is saturated with iron. Flux and binding components (bentonite clay) are added to the mixture (finely ground ore concentrate). Iron pellets are formed from this mixture.

- In terms of appearance, iron pellets are small gray-brown granules whose size usually varies in the range of 10 to 25 mm.

- According to the chemical composition of these pellets, the proportion of iron in the mixture is at least 65%. • These pellets are very resistant to aggressive environmental factors and have anti-corrosion properties.

- They have high strength and resistance against wear.

- Iron pellets are immune to sudden and long-term thermal fluctuations.

Production of iron pellets

- Iron pellets are made of fine grains of enriched iron from the mine. In the process of producing these pellets, iron is usually ground to a very fine size and mixed with limestone or dolomite as flux and bentonite or organic adhesives. If the ore is hematite, coke or anthracite coal can be added to the mixture to act as an internal fuel to help ignite the pellets. This mixture is mixed in a mixer and placed on discs or drums to produce green seeds, usually 9-16 mm in size. Then the green granules enter the compression machine. In the next step, the pellets are heated to a temperature of about 800-900 degrees Celsius in the preheated section and then they complete the freezing process at about 1200-1350 degrees Celsius.

- It should be noted that by adjusting the amount of added flux or limestone, different iron pellets and granules can be obtained (from acidic (or non-lubricating) granules to highly lubricating granules).

Metallized iron pellets

- To obtain raw pellets, dish, drum or bowl-shaped pellet makers are used and they are strengthened by roasting or without baking. It should be noted that if up to 95% of iron oxide turns into metal in iron ore pellets, such pellets are called metallized. These pellets, as a rule, are used in the electric arc furnace and in the production of high quality steels.

The role of bentonite clay in the production of iron pellets

- In general, the volume of bentonite clay increases and becomes viscous when it interacts with water. This property allows bentonite to be used as an adhesive to produce iron pellets from iron ore concentrate (crushed wet iron ore that has passed the optimization stage).

- It is worth noting that the production of these pellets generally includes two stages:

- The formation of wet granules of the required size from the load of iron ore on pelletizers.

- Sintering these pellets in roasting machines to the extent that they can withstand long-term transportation, reloading, heating and melting in furnaces.

- Therefore, bentonite not only acts as an adhesive component, but also creates strong intergranular bonds that help reduce the formation of cracks under the influence of high temperature and give strength to the pellets.

Application of iron pellets

- Iron pellets are used in the production of steels for use in the construction of bridges, cars, airplanes, bicycles, household appliances, etc. In general, the use of pellets instead of sinter in steel factories reduces greenhouse gas emissions more! Because steel factories do not need baking. In fact, according to reports, steel production using iron pellets causes a 14% reduction in carbon dioxide emissions in the entire value chain.

- One of the most common applications of iron ore pellets is the production of iron-based products using a blast furnace. Because of the shape of the pellets, they can be placed in the oven and the right amount of hot air is passed in and around each sphere.

- This process is more efficient than using iron ore powder, because the rock powder does not allow hot air to circulate freely and heat the ore to a uniform temperature! For this reason, pellets are often preferred over fine iron ore powders and products! Because the ability to achieve this balance and uniformity of temperature in iron ore powder is limited.

Technological features of iron pellets

- Although iron pellets are made of very fine and almost powdery particles, the final product has good strength. These bullets are practically indestructible. It is non-toxic, non-flammable and non-explosive, and it can also be stored outdoors for a long time.

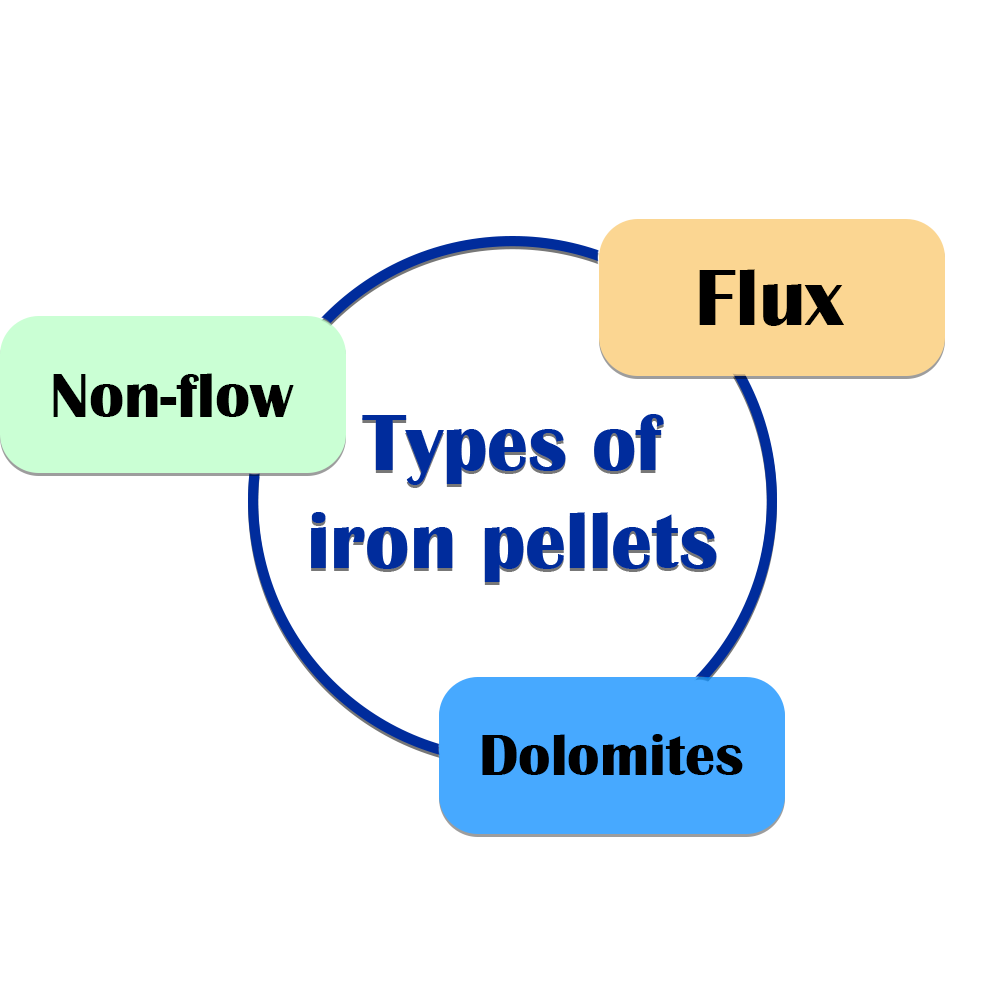

Types of iron pellets

- It should be noted that iron pellets, depending on their chemical composition, are divided into the following three types:

- Flux

- Non-flux

- Dolomite

The price of iron pellets

- In recent years, with the increase in global demand for the use of iron pellets, it is also increasing in global markets. It is worth mentioning that iron pellets have a very wide market and can be found in any market. However, the buying and selling of iron pellets is done in different ways, each method creates a different price for the buyer.

- One of the best ways that even manufacturers of iron pellets use this method to sell iron pellets is online shopping. Because in online sales, many side costs related to product mediation, such as transportation costs, advertising costs, etc., are eliminated and the final product is provided to customers at a more customer-friendly price. We suggest that you contact Ahan Mine consultants to get more detailed information in this field, including the price of iron pellets in the stock market.

The best shopping center for iron wheat

- It is necessary to explain that Iran Maad pellet factory can produce pellets of different grades/quality due to having a rotary kiln where the pellets are heated and cooked uniformly. In fact, Ahan Madan is one of the well-known and well-known centers in the distribution of high-quality types of iron pellets, which has been able to play an important role in meeting the needs of industrial customers for high-quality types of these pellets.

- Based on this, we suggest that if you need to buy iron pellets, contact the mining iron sales consultants and get the necessary guidance in this field. Also, the full-time support department is ready to meet all your information needs, including the price of iron pellets and the technical specifications of iron pellets of Ahan Mine.

- Iron pellets are mainly used in the steel industry and sponge iron production as a raw material for the production of cast iron and steel. It is also used in casting industries and production of ferroalloys. The use of pellets increases efficiency and reduces energy consumption in metalworking processes.

- The difference of iron pellets in different factories is due to the quality and type of primary iron ore, which may be obtained from different mines with different purity. The production process and the type of equipment are also different in each factory and can affect the strength and uniformity of the pellet. In addition, additives such as bentonite and lime, which are added to the pellet to improve strength and physical properties, vary depending on the standard of each plant. These differences lead to the production of pellets with different characteristics for specific applications.

- You can call the numbers on the site or leave a message so that our experts can guide you to prepare the pellets you want more easily.

Iron pellets are mainly used in the steel industry and sponge iron production as a raw material for the production of cast iron and steel. It is also used in casting industries and production of ferroalloys. The use of pellets increases efficiency and reduces energy consumption in metalworking processes.

Iron pellets vary from plant to plant due to the quality and type of iron ore, which may be produced with different purities. The production process and type of equipment also vary from plant to plant, which can affect the strength and uniformity of the pellet. In addition, additives such as bentonite and lime, which are added to the pellets to improve strength and properties, vary depending on the standard of each plant. This difference results in pellets with different properties for specific applications.

- You can call the numbers on the site or leave a message so that our experts can guide you to prepare the pellets you want more easily.