!!Buying cast iron ingots and everything we need to know about it

- If the purpose of your proud presence on this website is to know how to buy cast iron ingots, we suggest that you contact the iron ore sales consultants. Also, reading the rest of this article can be very fruitful in improving your knowledge about the nature of cast iron ingots as well as its types. So stay with us!

- In general, the presence of iron in everyday life began around 1200 BC and spanned a wide range of uses from agricultural implements to weapons of war. Blacksmiths became a sensitive profession and by working on iron, they tried to change its properties and turn it into other tools. Every village and city had a blacksmith shop where scythes, plows, nails, swords, candlesticks, etc. were produced. It is worth mentioning that the discovery of the value of iron and the dominance of this material in social and military applications led to the formation of the Iron Age.

- One of the most important iron products is cast iron ingot. Cast iron ingot is a high-quality iron element that is usually cast in the form of bars. This ingot contains very few impurities and is not processed. It should be noted that ingots can be obtained from iron mining and production companies. In this regard, Ahan Madan is one of the well-known companies in the supply and distribution of cast iron ingots in different shapes and sizes, which has been able to gain a significant reputation among customers. Based on this, to know how to buy cast iron ingots, you can contact the iron ore sales experts.

The nature of the bullion

- For thousands of years, people have used ingots when working with metals. Because it is easy to carry and move the ingot and this makes it convenient for use in mines. It should be noted that the size and shape of an ingot varies depending on the technical specifications of a particular metal, but it is usually supplied to industrial markets in the form of small rectangular bars (small enough to be moved, but not too small).

- The ingot may also have a slightly conical shape and is usually stamped with a mark that shows which company made it and probably which manufacturer it belongs to. The seal inserted on the bullion can be in the form of a company logo, a printed word or a series of words. One of the most common types of ingots is iron ingots, which are often made of cast iron and are also known as cast iron ingots. It should be noted that cast iron ingots are not pure iron and are usually used to make other iron alloys.

The nature of cast iron ingots

- To get more information about the nature of cast iron ingots and how to buy cast iron ingots, you can contact Ahan Mine experts. It is worth mentioning that cast iron ingots are produced by melting iron-carbon alloys whose carbon content is more than 2%. After melting, the metal is poured into the mold. Cast iron ingots contain 2-4% carbon and other alloys and 1-3% silicon, which improves the casting performance of the molten metal. Small amounts of manganese and some impurities such as sulfur and phosphorus may also be present in it.

- Also, in the difference between cast iron ingots and steel ingots, it should be noted that although steel and cast iron both contain traces of carbon and look similar, however, there are significant differences between these two metal ingots. As such, the steel contains less than 2% carbon, which enables the final alloy to freeze into a microcrystalline structure. This is while the cast iron ingot contains much more carbon.

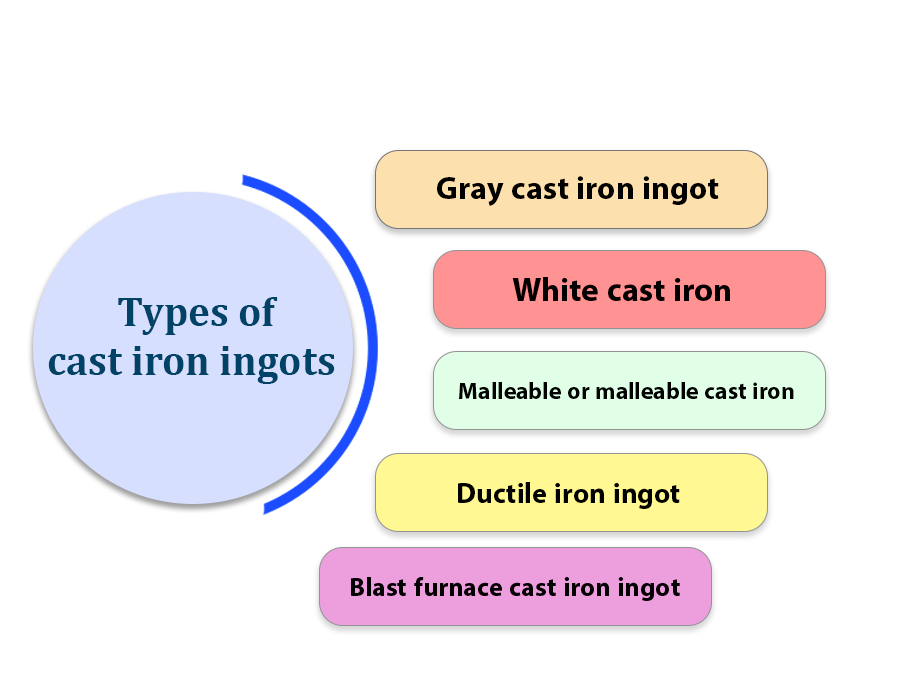

Types of cast iron ingots

- In the production method of cast iron ingots, it should be mentioned that these ingots can be produced by two classical casting methods or mechanically. In general, cast iron ingots are a combination of high carbon content and the presence of silicon, which gives cast iron excellent castability. Different types of cast iron ingots are produced using different heat treatment and processing methods, including gray iron, white iron, malleable iron, ductile iron, and compressed graphite iron. Some of the most important types of cast iron are discussed below:

Gray cast iron ingot

- This type of cast iron ingots is unique in terms of properties and chemical composition, and part of the carbon in them is separated into free graphite in cast iron at low temperature. It is worth mentioning that the characteristics of this type of cast iron can vary depending on the distribution of graphite flakes and the degree of hardness of the metal around the graphite.

White cast iron

- White cast iron is another type of cast iron whose most important characteristics are fragility, brittleness and hardness. This type of cast iron is used in a non-alloy form and with large amounts of carbide elements such as vanadium or cream.

Malleable or malleable cast iron

- This type of cast iron is produced from white cast iron during a very long heat treatment which is approximately equal to 100 hours. The most important characteristic of this cast iron is that carbon is dispersed in the field in a spongy form.

Ductile iron ingots

- This type of cast iron consists of various amounts of magnesium, phosphorus, sulfur, manganese and silicon, and because of its spherical graphite structure, it has a very high resistance.

Blast furnace cast iron ingots

- One of the most authentic and oldest furnaces widely used in steelmaking and metallurgy industries is the blast furnace. In these furnaces, the material used to provide energy is coke, and melting of items is done continuously in a high volume. It should be noted that the cast iron ingot produced in this way is one of the ingots that needs to be modified in order to convert it into other iron derivatives, including steel.

- It is necessary to explain that to get more information in the field of cast iron ingots and also how to buy cast iron ingots, you can contact the experts.

Technical specifications of cast iron ingots

- Among the most important technical characteristics of cast iron ingots, we can mention the properties of silicon element in it. This element has led to the formation of several metallurgical effects in cast iron! And by creating a completely sticky surface oxide, it significantly improves the resistance of cast iron against corrosion and oxidation. For sure, iron ore consultants can provide you with more technical specifications of this product, and therefore, if you need to get any more information in this area, as well as the price of cast iron ingots, you can contact the iron ore specialists. .

- White and gray cast iron ingots are different due to the difference in carbon structure and cooling method. White cast iron has a hard and brittle structure because there is carbon in it in the form of iron carbide (cementite) and it creates a shiny and white surface. In contrast, gray cast iron has a softer and more malleable structure because the carbon is distributed as graphite in its structure, giving it a gray color. These features make a difference in their industrial applications.

- The main difference between cast iron ingots and steel ingots is their carbon content and crystal structure. Cast iron ingots have more carbon (more than 2%) which makes them brittle and therefore suitable for parts that require high strength and low ductility. In contrast, steel billet has less carbon (less than 2%) and creates a more flexible and resistant structure that is suitable for structural and industrial parts that require greater pressure tolerance and shaping.

- You can call the numbers on the site or leave a message so that our experts can guide you to get the cast iron ingot you want more easily.

White and gray cast iron ingots differ in their carbon structure and cooling method. White cast iron has a hard and brittle structure because the carbon is present in it in the form of iron carbide (cementite), creating a shiny, white surface. In contrast, gray cast iron has a softer and more malleable structure because the carbon is distributed in the form of graphite in its structure, giving it a gray color. These characteristics cause differences in their industrial applications.

The main difference between cast iron and steel ingots is their carbon content and crystal structure. Cast iron ingots have more carbon (more than 2%), which makes them brittle and therefore suitable for parts that require high strength and low ductility. In contrast, steel ingots have less carbon (less than 2%) and create a more flexible and resistant structure, which is suitable for structural and industrial parts that require greater stress tolerance and forming.

- You can call the numbers on the site or leave a message so that our experts can guide you to get the cast iron ingot you want more easily.