!!!Buying graphite electrode, and everything you need to know about it

- Today, the production of graphite electrode is done by various workshops, one of the most important reasons of which is that this product is widely used in the steel industry. In the meantime, what is very important is to provide quality types of this electrode from reliable distribution and supply centers. In this regard, iron ore sales consultants can provide you with the necessary guidelines in the field of graphite electrode purchase. It is worth noting that our company until the end of the article is very important in improving your understanding of the nature and function of these electrodes!

- Graphite electrodes have high electrical conductivity and are highly resistant to high temperatures! And this is precisely why graphite electrodes are referred to as a standard tool to accelerate the melting process in electric arc furnaces. In the graphite electrode, as its name suggests, graphite is an essential element for its operation. These electrodes are immersed in metal waste and act as a heat source. It should be noted that the use of these electrodes is very widely used for refining and melting processes of metal waste, iron ore and other raw materials. That is why, in this article, we intend to present the nature of graphite electrodes and how to use them in furnaces and take a useful step in expanding the literature related to the metallurgical industry.

The nature and process of making graphite electrode

- In the following, the nature and process of making graphite electrode will be discussed. Charcoal electrode is a kind of graphite conductive material resistant to high temperature, which uses petroleum coke as aggregate and coal rock as binder, after calcining the raw materials, crushing and grinding, batching, kneading. It is made by mixing and extrusion, baking and impregnation. It should be explained that graphite electrodes are mainly used for steel production in electric arc furnaces. These electrodes have a high ability to maintain very high levels of heat produced and are used in steel refining and similar melting processes. To get more information about the process of making and buying graphite electrodes, you can contact Ahan Madan.

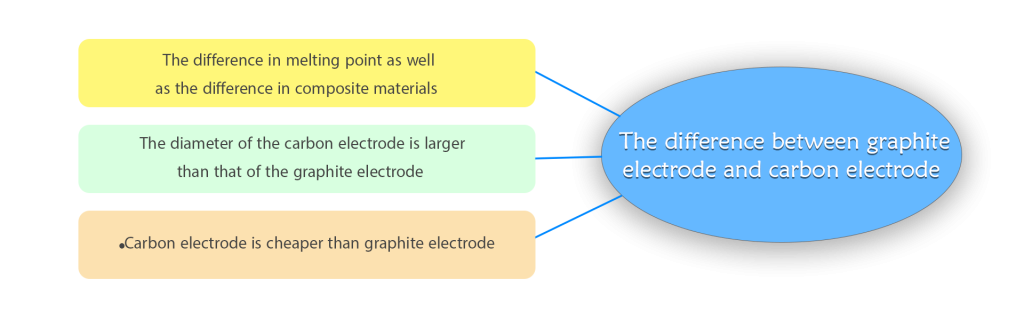

The difference between graphite electrode and carbon electrode

- To get more information about the difference between these two electrodes, as well as to buy graphite electrodes, you can contact the iron and steel collection. Below are some examples of the most common differences between graphite electrode and carbon electrode.

- A carbon electrode is composed of carbon, but does not contain graphite. The sintering temperature of this powder after formation is only 1000 degrees Celsius and no graphitization process is applied in it. This is while the graphite electrode is made from petroleum coke and bitumen coke and then placed in graphite resistance furnaces with a temperature of 2000 to 2500 degrees Celsius.It is worth mentioning that sintering temperature means heating the powder at a temperature (70 to 80% of the melting point) below the melting temperature of the substance, so that at this temperature, the powders of the substance can bond.

- The diameter of the carbon electrode can be large (between 650 and 1200 mm), while the internal diameter of the graphite electrode is only 700 mm.

- Carbon electrode is mainly used in industrial silicon, yellow phosphorus, calcium carbide, ferroalloy and other melting furnaces, while graphite electrode is mainly used in electric arc furnace steelmaking.

- Carbon electrode is cheaper than graphite electrode.

?What is an electric arc furnace

- Electric arc furnaces are metal melting furnaces that convert electrical energy into heat during operation. The construction of these furnaces is very simple and has a container with a fireproof coating and a lid through which the electrodes are inserted. As mentioned above, graphite electrodes are a standard tool for use in this type of furnace in the metallurgical industry.

- According to the amount of electric current that passes through the graphite electrodes, the temperature of these electrodes can increase to more than 3500 degrees Celsius. It is necessary to explain that depending on the type of furnace construction, alternating current (AC) or direct current (DC) can be used. In the case of steel, about 400 megawatt hours of electrical energy is needed to produce one ton of steel.

How to use graphite electrodes

- To start the furnace, waste or iron ore is put into the furnace and sealed with its lid to prevent accidents. Then, with the help of a hydraulic system, the electrodes are slowly inserted into the furnace chamber through the door openings.

- It is worth mentioning that these electrodes have the ability to connect to each other, and in the same way, the final length of the electrode inserted into the furnace can be different. The electrodes are screwed into a socket like the incandescent lamps we all know. In this way, a large amount of electric current can be passed through them. At the end of the operation, the electrodes are extracted by the hydraulic system and the molten metal is transferred or discharged to make steel products.

- It should be noted that due to the extreme temperature of the melting process, the presence of oxygen and the catalytic effect of temperature, graphite electrodes gradually begin to decompose or oxidize and sublimate to CO2. Therefore, these electrodes must be periodically replaced for the proper functioning of the furnace.

Graphite electrode price

- In general, two examples of important parameters affecting the price of graphite electrodes in Iran can be presented as follows:

Apparent density

The greater the weight of the electrode, the better its performance properties.

The quality of graphite forming the electrode

In other words, the quality of graphite is an important factor for the proper functioning of the electrode at very high temperatures.

- Based on this, it can be expected that the price of graphite electrode is not limited to a specific range and is offered to the market in a different price range. In addition, the way of supply is also very important in determining the final price of this product! For example, in direct supply and distribution and removing all intermediary costs, including transportation costs, the desired electrode is provided to the end customers at a much lower cost.

- We suggest that you contact the iron ore sales experts to access the price of graphite electrode, the best and cheapest graphite electrodes in the market, and also to buy graphite electrode.

- Due to its high temperature resistance and excellent electrical conductivity, graphite electrode is used in industries such as steelmaking (for electric arc furnaces), aluminum production, and chemical industries for electrolysis processes. It is also used in the production of ferroalloys and other special metals. These electrodes are ideal for transferring electric current in very high temperature processes.

- The density of the graphite electrode has a direct effect on its price; Electrodes with higher density are usually of higher quality because they offer greater electrical conductivity and mechanical strength. The production of these electrodes is more complicated and expensive, so their price is also higher. Higher density electrodes are preferred in sensitive industrial applications and high temperatures.

You can call the numbers on the site or leave a message so that our experts can guide you to get the graphite electrode you want more easily.

Graphite electrodes are used in industries such as steelmaking (for electric arc furnaces), aluminum production, and the chemical industry for electrolysis processes due to their high temperature resistance and excellent electrical conductivity. They are also used in the production of ferroalloys and other specialty metals. These electrodes are ideal for conducting electrical current in very high temperature processes.

The density of a graphite electrode has a direct impact on its price; electrodes with higher densities are usually of higher quality, as they offer greater electrical conductivity and mechanical strength. These electrodes are more complex and costly to manufacture, so their price is also higher. Electrodes with higher densities are preferred in sensitive industrial applications and high temperatures.

- You can call the numbers on the site or leave a message so that our experts can guide you to get the graphite electrode you want more easily.