?What is iron ore concentrate and what are its uses

- Iron ore concentrate is actually a product produced from iron ore that is produced at the end of multiple processes. Today, this substance is transported in bulk through air transportation methods. In this article, we will fully review the important points related to the purchase of iron ore concentrate and its production method.

- In the past, only minerals specific to this element were used to produce iron. But nowadays, due to the increase in the global demand for iron element, other compounds containing iron are also used to produce this element. Of course, it should be noted that the grade of iron obtained from secondary compounds is relatively low.

Table of contents

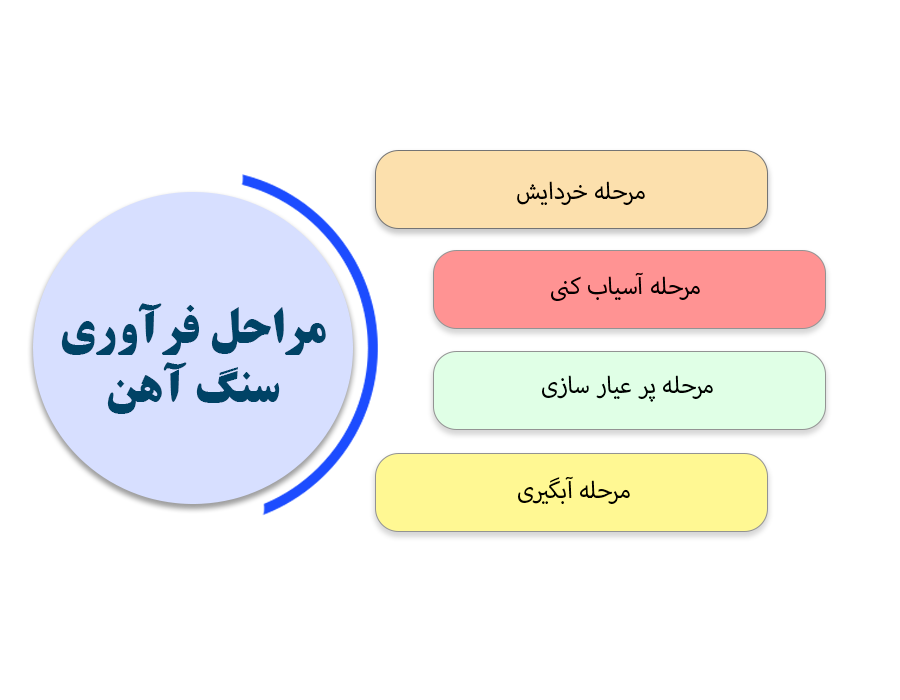

:Types of iron ore processing methods

- You can use two different methods to process iron ore. Each of the processing methods has unique characteristics, advantages and disadvantages. Also, their output product is also different in terms of features, application, etc. The production of granulated iron ore and the production of iron ore concentrate are actually the main methods of iron ore processing, which provide you with this element in different grades. When buying iron ore concentrate, you have to pay more than granulated iron ore. Because the processing method of iron ore concentrate is in a way that produces a higher quality product

:General stages of iron ore processing

:Cutting step

- Crushing stage is the first stage of iron ore processing. At this stage, the raw material has reached the industrial unit and its dimensions are transformed into stones smaller than 20 to 25 cm. Note that at this stage you can use different stone crushing methods. For example, cone crusher is one of the methods used in most iron ore processing units. It should be noted that at this stage excessive crushing and crushing of raw materials with suitable dimensions is avoided.

:Grinding step

- The grinding stage is the second stage of iron ore processing. This step is done in a more uniform way, unlike the grinding which was done completely dry. In the damaging stage, self-destructive, roller or semi-self-destructive damages are used, and the dimensions of the first material are reduced to about 1 mm. After reaching the dimensions of 5 to 1 mm, the raw materials enter the ball mills so that their dimensions continue to decrease.

:Refinement stage

- The stage of high grade is one of the important stages of iron ore processing, which can affect the final price of the iron ore concentrate. In this step, the valuable materials in the crushed materials are separated from the waste. This process is carried out by sliding guides and magnetic separators. It should be noted that special methods are used to separate some materials. For example, phosphorus and sulfur in concentrate are separated from iron with the help of flotation method

:Watering stage

- In the dewatering stage, we see the presence of precious iron obtained from the previous stages. In this step, special filters are used to absorb iron ore concentrate water. These filters can significantly reduce the moisture in the iron concentrate and bring it to about 9-10%. The concentrate obtained from this step can be transferred to product storage warehouses and then reach consumers.

The difference between granulated iron ore and iron ore concentrate

- Granulated iron ore has significant differences with iron ore concentrate. In addition to the high purchase price of iron ore concentrate, the production method and structural features of these materials are also different from each other. For example, granulated iron ore is produced in a completely dry process. While for the production of iron ore concentrate, you need to use the wet roasting method and the dewatering stage.

- Granulated iron ore is also different from iron ore concentrate in terms of application. Due to its low quality, this material cannot be used in the direct regeneration system, and you can use it in blast furnaces. While the applications of iron ore concentrate are more and it has the ability to use direct regeneration methods.

The reason for processing iron ore and turning it into iron ore concentrate

- Raising the grade is the main reason for processing iron ore. Today, there are many different compounds in nature that contain iron. Some of these compounds contain a significant weight percentage of iron element. But still you can’t use it. Iron ore processing helps you to significantly increase the grade of iron element and to separate its impurities. This process has advantages such as reducing costs, increasing efficiency, reducing pollution, etc.

:Important points in the field of buying iron ore concentrate

:Buying iron ore concentrate from a reputable brand

- Today, various domestic and foreign companies are active in the production of iron ore concentrate. We advise you to pay special attention to the brand and company producing the product as well as the country of its production when using iron ore concentrate. Concentrators produced by some brands have better quality and can bring you more efficiency. Chinese iron ore concentrate, Sirjan iron ore concentrate, etc. are examples of the most well-known products in the country’s market.

- You can also click on the text to buy iron pellets from Ahan Mine.

:Grade of concentrate

- It is possible to buy low, medium and high grade iron ore concentrate. The grade of concentrate is one of those things that can have a very significant effect on the application, place of consumption and final efficiency of the product. We advise you to pay more attention to the quality of your desired product than other materials when buying iron ore concentrate so that you can get the best feedback.

:Methods of buying iron ore concentrate

- There are different ways to buy iron ore concentrate. As he said, today many domestic and foreign brands are active in the production and sale of these products. Currently, you can purchase iron ore concentrate in person or in person (refer to the website of your desired brand). Each of the above purchase methods has unique advantages and disadvantages. We advise you to pay special attention to the history of the company or the website of the place of purchase when shopping offline.

- In addition to the high purchase price of iron ore concentrate, the production method and structural features of these materials are also different from each other. For example, granulated iron ore is produced in a completely dry process. While for the production of iron ore concentrate, you need to use the wet roasting method and the dewatering stage.

- Raising the grade is the main reason for processing iron ore. Today, there are many different compounds in nature that contain iron. Some of these compounds contain a significant weight percentage of iron element. But still you can’t use it. This process has advantages such as reducing costs, increasing efficiency, reducing pollution, etc.

- You can call the numbers on the site or leave a message so that our experts can guide you to prepare the pellet you want more easily.

Communication bridges

Time table

Providing an official invoice

Shipping to all locations

Best price guarantee

Check sale

Taban Asia Steel Company, under the brand name of Ahan Madan, is a consortium of long-standing players in the steel industry, which, relying on the technical and specialized power and years of experience of the steel veterans working in these companies, works in the direction of meeting the needs of customers and their conscious purchase from the Iranian steel market. does Relying on our hardware support, such as a warehouse with an area of ten thousand square meters with a covered hall, supplying and trading all steel sections, providing valid certificates to guarantee the quality of products, support services until the moment of delivery, and also providing special services for the country’s manufacturing industries on an exclusive basis. , is trying to create a safe environment for consumers.

- All material and intellectual rights are reserved for this site

- Design and SEO of Taban Asia Steel Company